What are the steps of etching?

The etching process has the following steps:

1. Incoming material inspection when receiving the workpiece required to be processed by the customer, we should first clean the workpiece received from the customer through inspection, that is, the work to be done in our current IQC process, and then conduct careful inspection to remove the defective products in the incoming material to ensure that the input products are good products.

2. Electrostatic dedusting, spraying photosensitive oil and checking. When the workpiece processed by the incoming material passes the IQC inspection, it will be handed over to the next process: spraying photosensitive oil, but electrostatic dedusting must be carried out before spraying photosensitive oil, because static electricity will exist to varying degrees in the production process and our wiping test process, and static electricity can absorb dust, so it is necessary to pass electrostatic dedusting, After the static electricity is removed, the dust will not be absorbed on the product. After the static electricity is removed, proceed to the next step: spray photosensitive oil. The function of spraying photosensitive oil is mainly to prepare for the photosensitive (light exposure) of the next process. Spray photosensitive oil on the front and back of the product. After the oil injection, it is necessary to carefully check the product, The purpose of checking is whether the product is sprayed with oil, whether there is residual oil residue and other adverse phenomena during the fuel injection process. When the product is checked to be OK, it will flow into the next process: photosensitivity (exposure).

3. Photosensitive and developing photosensitive (exposure) is to place the film on the product sprayed with photosensitive oil. The main purpose is to make the picture on the film form on the product through exposure. During the photosensitive (exposure) process, pay special attention to the fixture. The film cannot be tilted, otherwise the picture of the product will be tilted, and then defective products will be produced, and the film should also be checked regularly, No folding, otherwise defective products will appear. After the photosensitivity (exposure) is completed, the next step should be carried out: development; The purpose of development is to wash away the unexposed area through the development potion, and form an etched picture through the local solidification of the exposure. After development, the quality inspector will check the product, select the products that cannot be developed or have bad pictures, and the good products will enter the next process: oil sealing.

4. The so-called oil sealing is to manually replenish the product at the marginal position of the product and where the oil cannot be sprayed during the oil injection process. The metal parts of the product shall not be exposed during the oil replenishment process, otherwise defective products will be produced after etching. After the oil replenishment is completed, the product shall be dried, and the product shall be checked after drying, After checking OK, it can be put into the next process: etching.

5. Etching, cleaning and etching are the key processes of the whole production process. They mainly corrode the exposed stainless steel parts of the product through the chemical action of chemical solution, and then form the picture we want. After the etching work is completed, clean the product and remove the excess paint, Then finish the processing of the product through the cleaning equipment such as slow drawing machine.

6. The products after the completion of etching and cleaning process are the products we want, but FQC final inspection should be carried out to remove the defective products in the production process before they can be delivered to the finished product warehouse for shipment.

Article from:http://www.juxinwujin.cn

-

11-29

Is it difficult to etch stainless steel?

Stainless steel etching process is mainly reflected in the control of stainless steel etching process and whether the equipment for stainless steel etching process meets the skill requirements.The etching process itself is relatively complex, and there are many links that need to be controll

-

11-28

What are the uses of metal etching?

What are the uses of metal etching?(1) Deburring. After punching or machining, there are burrs on the end face or edges and corners of the stainless steel plate, which will not only affect the appearance of the product, but also affect the use effect of the machine. If mechanical polishing o

-

11-25

Introduction to the precision of stainless steel etching

The concept of stainless steel etching accuracy is very abstract, because the materials of etching include stainless steel, copper, copper alloy, molybdenum plate, aluminum plate, etc. the etching accuracy will be different with different materials.Moreover, the thickness and pattern of etch

-

11-20

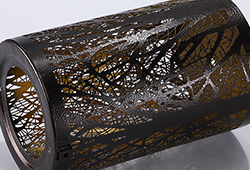

Can the filter screen be etched?

The filter screen can be processed by etching. It is mainly used for air conditioners, purifiers, range hoods, air filters, humidifiers and dust collectors. It is suitable for various filtration, dust removal and separation requirements, and for filtration in petroleum, chemical, mineral, food,