What should we pay attention to in the etching process?

Precautions in stainless steel etching process?

Processing area: the processing area of stainless steel parts shall be relatively fixed. Isolation measures shall be taken for the platform in the stainless steel parts processing area, such as paving rubber pads, etc. The processing area of stainless steel parts shall prevent damage and pollution to stainless steel parts.

Blanking: cutting or plasma cutting, sawing, etc. are used for blanking of stainless steel parts.

Machining: stainless steel parts shall also be protected during machining such as turning and milling. At the end of the operation, the oil stain, iron filings and other sundries on the surface of the workpiece shall be cleaned.

Forming processing: in the process of plate rolling and bending, effective measures shall be taken to prevent the surface scratch and crease of stainless steel parts.

Article from:http://www.juxinwujin.cn

-

11-29

Is it difficult to etch stainless steel?

Stainless steel etching process is mainly reflected in the control of stainless steel etching process and whether the equipment for stainless steel etching process meets the skill requirements.The etching process itself is relatively complex, and there are many links that need to be controll

-

11-28

What are the uses of metal etching?

What are the uses of metal etching?(1) Deburring. After punching or machining, there are burrs on the end face or edges and corners of the stainless steel plate, which will not only affect the appearance of the product, but also affect the use effect of the machine. If mechanical polishing o

-

11-25

Introduction to the precision of stainless steel etching

The concept of stainless steel etching accuracy is very abstract, because the materials of etching include stainless steel, copper, copper alloy, molybdenum plate, aluminum plate, etc. the etching accuracy will be different with different materials.Moreover, the thickness and pattern of etch

-

11-20

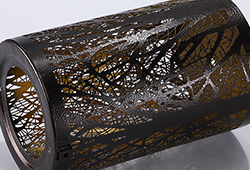

Can the filter screen be etched?

The filter screen can be processed by etching. It is mainly used for air conditioners, purifiers, range hoods, air filters, humidifiers and dust collectors. It is suitable for various filtration, dust removal and separation requirements, and for filtration in petroleum, chemical, mineral, food,